ECT-KEMA laboratory extruders set the standard - worldwide!

They can be found in many renowned ceramics laboratories, both in industry and in scientific institutes, for the field of technical ceramics as well as for laboratory purposes in connection with the manufacture of fine or heavy ceramic products.

For special requirements, we have developed laboratory extruders that can record and log up to 25 different operating parameters online, such as radial and axial extrusion pressures, torques, temperatures, strand speeds, etc.

An overview of our portfolio for laboratory extruders and laboratory vacuum extruders can be found here.

ECT-KEMA_Lab_Extruders

ECT-KEMA_Lab_Extruders_Enquiry

For special requirements, we have developed laboratory extruders that can record and log up to 25 different operating parameters online, such as radial and axial extrusion pressures, torques, temperatures, strand speeds, etc.

An overview of our portfolio for laboratory extruders and laboratory vacuum extruders can be found here.

ECT-KEMA_Lab_Extruders

ECT-KEMA_Lab_Extruders_Enquiry

Micro Extruder EXRS 35 „PAUL“

Application

- Extrusion of ceramic profiles and pellets with diameters between 1-25 mm

- Designed as a high-quality measuring extruder for determining rheological characteristics

- Shaping, extruding or pelletizing complex geometries in the lab and in production

- Dimensioned for radial pressures up to 300 bar

- Intended for minimum fill volumes of 0.2 liters during development in the laboratory

Features

ECT-KEMA_EXR35_PAUL

Request

- Diameter auger: 35 mm

- Max. Pressure: 300 bar

- Dimensions: (L/B/H): 1400 x 800 x 1950 mm

ECT-KEMA_EXR35_PAUL

Request

Micro Vacuum Extruder VAQRS 35 „DOMINIK“

Application

.

- Micro extrusion of powder metallurgical, ceramic and related masses with diameters between 0.5-25 mm

- Shaping, extruding or pelletizing of complex geometries in the laboratory and in production

- Dimensioned for axial pressures up to 300 bar

- Intended for minimum filling volumes from 0.2 liters during development in the laboratory

.

Features

ECT-KEMA_VAQRS35_DOMINIK

Request

- Diameter auger: 35 mm

- Max. pressure: 300 bar

- Dimensions: (L/B/H): 1600 x 1200 x 2000 mm

ECT-KEMA_VAQRS35_DOMINIK

Request

Vacuum Extruder VAQRS 50 „DOMINIK“

Application

- High pressure extrusion unit for laboratory use

- production of small ceramic profiles

- suitable for pressures up to 150 bar

- Research and development

Features

Request

- Diameter auger: 50 mm

- Max. pressure: 150 bar

- Throughput rate: 25 l/h

- Minimum filling quantity: ca. 1 litre

Request

Vacuum Extruder VAQRS 80 „DOMINIK“

Application

- Use in production and laboratory

- Research and development

- for the production of ceramic profiles of 40 to 50 mm diameter

- optimal for minimal contamination of the ceramic mass

- for radial pressures up to 200 bar

Features

Request

- Diameter auger: 80 mm

- Max. pressure: 200 bar

- Throughput rate: 30-50 l/h

- Dimensions: (L/B/H): 1.8 x 1.5 x 1.8 m

Request

Vacuum Extruder VALRV 50 „LINA“

Application

.

- Continuous dosing of the extrudate through the vertical pre-press is guaranteed in the VALRV 50 laboratory extruder.

- Feeding of the material into the hopper is facilitated by a large drop-in opening and a conical screw rotating therein.

- A swivel-lift device allows the prepress to be decoupled from the extruder in a very short time and cleaned separately in the simplest way.

- Optional: temperature control of screw and barrel in the extruder, sensor system for measuring and logging pressure, temperature and torque

.

Features

Request

- Diameter auger: 50 mm

- Max. pressure: 340 bar

- Throughput rate: 8–12 l/h

- Dimensions: (L/B/H): 1.4 x 1.0 x 1.5 m

Request

Vacuum Extruder VALRP 50 „LINA“

Application

- Filling of the extruder or the dosing of the compound realized with a pneumatic piston

- swiveling two-chamber magazine for continuous metering during extrusion

Features

Request

- Diameter auger: 50 mm

- Max. pressure: 340 bar

- Throughput rate: 8–12 l/h

- Dimensions: (L/B/H): 1.4 x 1.0 x 1.5 m

Request

Laboratory Extruder VALRM 80 „LINA“

Application

- in the lab

- for pressures up to 50 bar

- available in 3 modular versions:

version M: with manual lever to be confirmed manually

Version P: with pneumatically operated plunger

Version V: with vertical prepress

Features

Request

- Diameter auger: 80 mm

- Max. pressure: 50 bar

- Throughput rate: 3 l/h

- Dimensions: (L/B/H): 1.5 x 1.2 x 1.5 m

Request

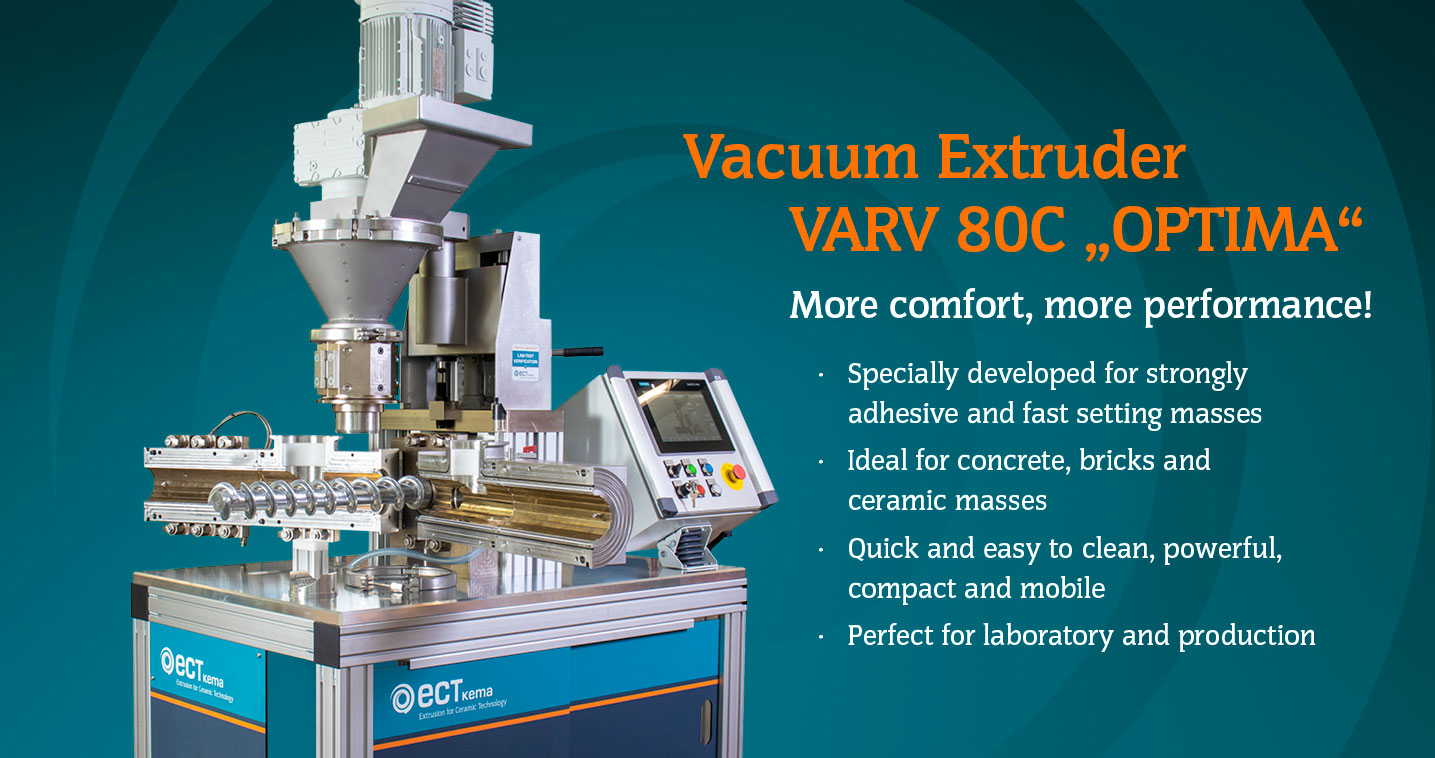

Laboratory Extruder VARV 80 „OPTIMA“

Application

- in the laboratory and production

- especially for adhesive and strongly setting compounds

- quick and easy to clean

Features

ECT-KEMA_VARV80_OPTIMA

Request

- Diameter auger: 80 mm

- Max. pressure: 50 bar

- Throughput rate: 40 l/h

- Dimensionen: (L/B/H): 1.4 x 0.8 x 2.2 m

ECT-KEMA_VARV80_OPTIMA

Request

PEN CHECK I, Typ CFG

Application

- Penetrometer for manual handling

- On-site evaluation of the plasticity of the masses to be extruded .

- Determination of the deformation resistance

- Use as a balance

- Measurement of tensile forces

Features

ECT-KEMA_PenCheck_I

Request

- digital display

- measured value display in kg, N, kN, oz, lb

- internal memory

- RS 232 interface for data transmission

- Data transmission with optional software

- Penetration needles of different geometries available

- Accuracy ±0.5%

- Measuring range 0 - 200 N

- Weight 200 g

ECT-KEMA_PenCheck_I

Request

PEN CHECK III

Application

- Penetrometer for laboratory and in-situ measurement

- On-site assessment of the plasticity of the masses to be extruded

- Determination of deformation resistance

- Use as a balance

- Measurement of tensile forces

Features

Request

- Force gauge AFG for forces 500 - 25000 N

- Force gauge detachable for manual measurement

- motorized test stand for precise preselection for indentation depth and indentation speed

- pressure or displacement based measurement of deformation force

- suitable for compression and tensile tests

- internal memory

- interface for data transmission

Request

Quickplast PPG - The rapid tester for measuring and comparing body plasticity and flow behaviour

Exact measurement of important parameters

Analysis of rheological properties

- Determination of the flow pressure without wall friction

- Determination of the yield point

Analysis of rheological properties

- Structural viscosity

- Shear thickening (dilatancy)

- Rheopexy

- Thixotrophy

Definition of parameters for quality control

ECT-KEMA_Quickplast_PPG

Request

- Specification of minimum and maximum values

- Comparative measurements

ECT-KEMA_Quickplast_PPG

Request

CAPILLAR CHECK with KP 35 "CLARA"

Application

- Discontinuous microextrusion of powder metallurgy, ceramic and related bodies with diameters from 0.5 to 25 mm

- Application as a high-grade measurement extruder for determination of rheological characteristics

- Shaping, extrusion or pelletization of complex geometries in the laboratory and production

- Dimensioned for axial pressures up to 340 bar

- For laboratory development applications, designed to handle minimum filling quantities from 50 ml

Features

ECT-KEMA_PB_KP35_CLARA_EN.pdf

Request

- Piston diameter: 35 mm

- Max. pressure: 340 bar

- Dimensions: (L/B/H): 9.6 x 1.3 x 2.2 m

ECT-KEMA_PB_KP35_CLARA_EN.pdf

Request