Storing, buffering, feeding, dosing

Box feeders are firmly established in the recycling industry, in the extrusion of solid or hollow strands, in the brick industry and in the feeding of biogas plants.

On the one hand, they act as storage or buffers; on the other hand, they transfer the material to the next machine for further processing.

Thanks to the infinitely variable speed of the belt and a height-adjustable pusher at the material discharge, the desired material throughput can be optimally controlled and metered. In addition, the reel shaft ensures uniform material discharge.

On the one hand, they act as storage or buffers; on the other hand, they transfer the material to the next machine for further processing.

Thanks to the infinitely variable speed of the belt and a height-adjustable pusher at the material discharge, the desired material throughput can be optimally controlled and metered. In addition, the reel shaft ensures uniform material discharge.

Circular Feeder RB 1500

Application

- Integration into existing conveyor lines as material buffer

- Feeding and portioning of ceramic masses as slugs, filter cakes or similar

Features

RB_1500_EN

Request

- Vessel diameter: 1500 mm

- Screen height: 750 mm

- Dimensions: (L/B/H): 2300 x 1330 x 2150 mm

RB_1500_EN

Request

Aufbereiten & Homogenisieren

In der Tonindustrie erzielt der Siebrundbeschicker beste Aufbereitungsergebnisse. Das Durchstreichen des Tones durch die Siebe garantiert die exzellente Homogenisierung der Masse. Die hierbei entstehenden Tonnudeln werden von dem robusten und ringförmigen Sammelteller aufgenommen und mittels eines Abstreifarmes an die nachfolgende Maschine weitergegeben.

Rotary Screen Feeder SRB 1900

Application

- Addition of aggregates

- Addition of water and steam

- Homogenization of materials with slightly different moisture content

- Storing and continuous feeding between preparation and shaping

Features

SRB_1900_EN

Request

- Vessel diameter: 1900 mm

- Screen height: 500 mm

- Dimensions: (L/B/H): 3650 x 3400 x 3350 mm

SRB_1900_EN

Request

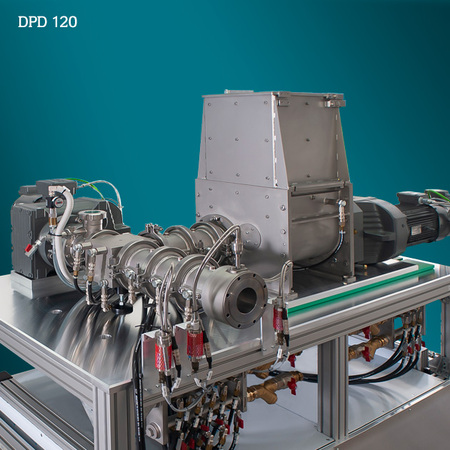

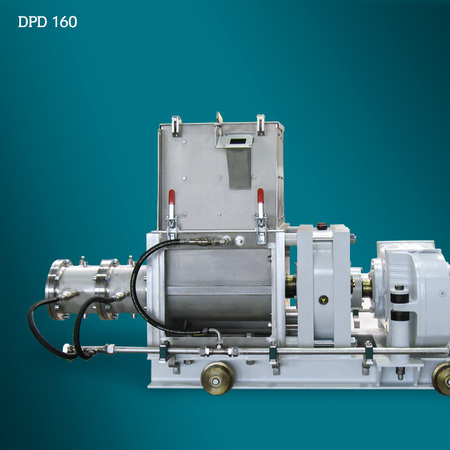

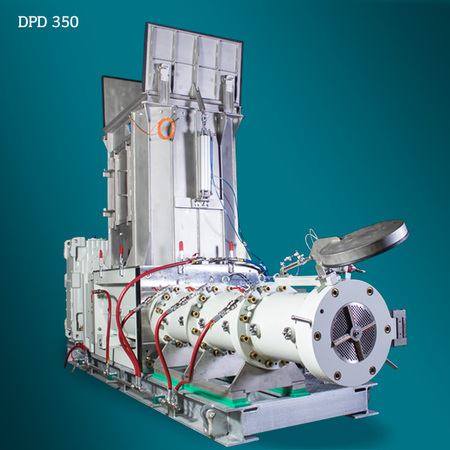

The right quantity at any time

Dosing trainers ensure the continuous supply of the compounds to be extruded. Depending on the requirements, feeding takes place as volumetric feeding with and without consideration of the degree of filling, as gravimetric feeding by means of a downstream belt weigher, or as feeding according to the differential weighing principle.

This makes the technically and economically problematic buffering of slugs or bulk material between discontinuously operating mixers/kneaders and continuously operating vacuum units a thing of the past.

This makes the technically and economically problematic buffering of slugs or bulk material between discontinuously operating mixers/kneaders and continuously operating vacuum units a thing of the past.

Application

- Dosierung plastischer keramischer Massen zwischen 20 und 2000 kg/h

- Buffering of volumes between 40 and 3000 liters

- Homogenization of mixed or kneaded masses

- Shredding by attaching perforated plates and rotary cutters

- Cleaning of the compounds by downstream screen changers

- use in combination with extruders as vacuum metering trainer

- use as pre-press

Dosing_Strainers_DPD_EN

Request

Filtering

Our filter presses are used successfully in many applications in the chemical industry, the food industry, biotechnology and the entire ceramic industry.

ECT-KEMA laboratory filter presses are perfectly suited for the solid-liquid separation of suspensions in small quantities in the experimental environment when developing advanced masses.

ECT-KEMA laboratory filter presses are perfectly suited for the solid-liquid separation of suspensions in small quantities in the experimental environment when developing advanced masses.

Laboratory filter press LFP 150

Application

Request

- Laboratory use

- Liquid filtration

- chemical industry

- food industry

- biotechnology

- Ceramics industry

Request

Filter Press FP 500 | FP 800

Application

Request

- Filtering of solids from suspensions of all kinds

- Heavy clay, fine and technical ceramics

- Chemical industry

- Food industry

- Environmental protection

Request