Chemische Industrie

- Bulk catalysts of different geometries

- Filigree honeycombs

- Pellets

Electro ceramic

- Columns for insulators up to 950 millimetres

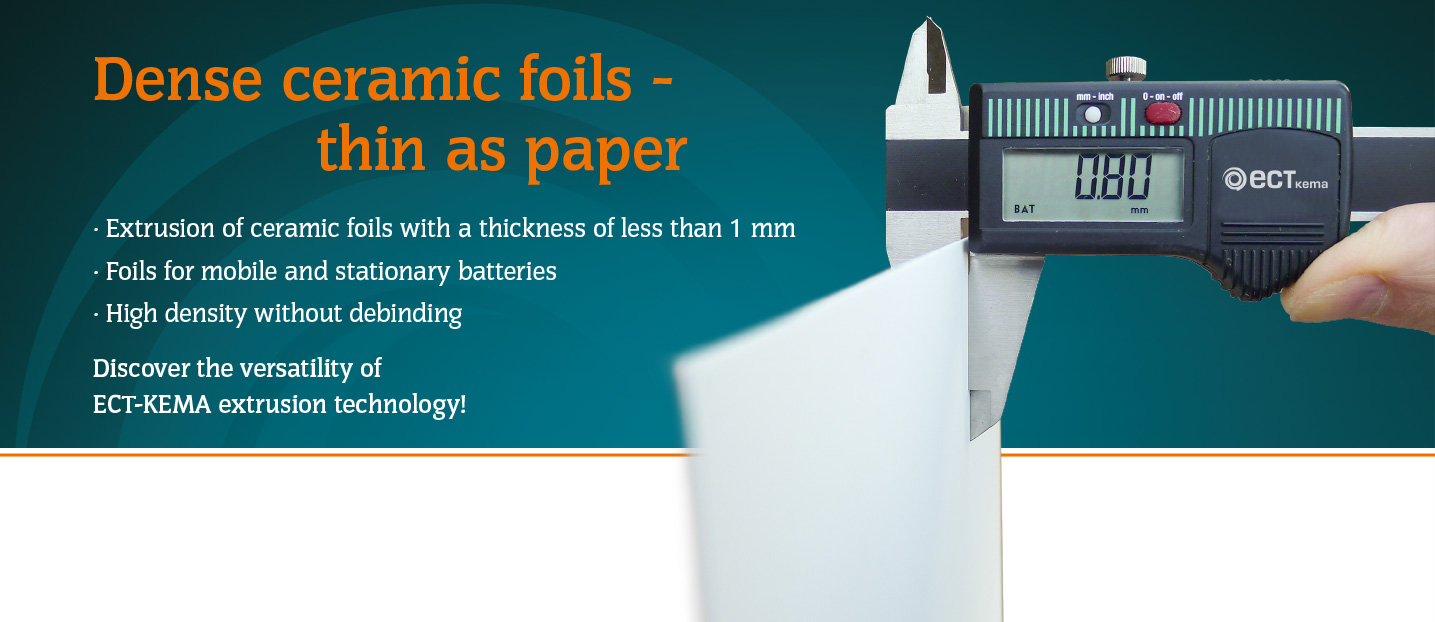

- "Thin foils"

Building materials industry

- Additive manufacturing by extrusion for concrete construction

- Production of bricks

- Shaping of adhesive and fast-setting masses

Automotive

- DENOX honeycombs for passenger cars

- SCI honeycombs for trucks and off-road applications

- DPF and CDPF for diesel engines

- Calotte tubes for fuel cells (SOFC)

Environment and recycling industry

- DENOX honeycombs for power plants

- Porous filter tubes

- Shredder heavy and light fraction

- Pelletizing residual materials and recycling material

Tool industry

- Tungsten carbide profiles

ECT-KEMA products are versatile. They are used worldwide in various industrial applications.

Close cooperation and know-how transfer with our partners from industry, research and development constantly open up new perspectives and areas of application for which > ECT-KEMA products represent the ideal solution.

With our many years of expertise in the field of extrusion of plastic masses, we develop and build customised > high-performance extruders according to our customers' requirements - economically, efficiently and sustainably.

Get an overview.

Technologies

Close cooperation and know-how transfer with our partners from industry, research and development constantly open up new perspectives and areas of application for which > ECT-KEMA products represent the ideal solution.

With our many years of expertise in the field of extrusion of plastic masses, we develop and build customised > high-performance extruders according to our customers' requirements - economically, efficiently and sustainably.

Get an overview.

Technologies