Pellets are produced and needed in almost all industries. Whether as wood pellets for heating, as ceramic pellets for catalysis in the chemical industry and - last but not least - as penne and macaroni for eating.

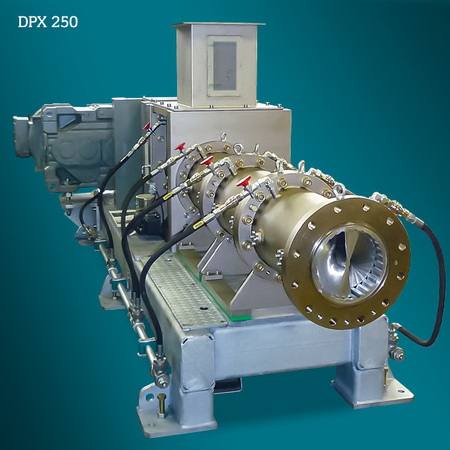

Within the agglomeration processes, extrusion belongs to the subgroup of press agglomeration.

Depending on the consistency of the material or the mass - powdery, slurry-like or plastic - various pelletizing processes are found in practice during shaping, preparation and in the laboratory.

Especially in the production of pellets from plastic masses, extrusion proves to be particularly advantageous.

We are particularly specialized in pelletizing ceramic and related masses, both in shaping and in preparation. Extrudates in the form of spheres, trilobes, quadrilobes and cylinders are part of our daily business.

We supply technology for every kind of pellets.

Request

Within the agglomeration processes, extrusion belongs to the subgroup of press agglomeration.

Depending on the consistency of the material or the mass - powdery, slurry-like or plastic - various pelletizing processes are found in practice during shaping, preparation and in the laboratory.

Especially in the production of pellets from plastic masses, extrusion proves to be particularly advantageous.

We are particularly specialized in pelletizing ceramic and related masses, both in shaping and in preparation. Extrudates in the form of spheres, trilobes, quadrilobes and cylinders are part of our daily business.

We supply technology for every kind of pellets.

Request