Versatile shaping

ECT-KEMA develops leading technology concepts for the extrusion of ceramic insulators from processing to shaping.

The latest generation of vacuum extruders from ECT-KEMA is perfectly equipped for the challenging transformation tasks in the energy transition. Especially for the production of high-performance insulators, power, efficiency, intelligence, and of course comfort are required. Our medium-pressure vacuum extruders combine this as a powerful overall package. With screw diameters ranging from 250 to 950 millimeters, they offer the entire range for the production of post insulators, high-voltage supports, and switch chambers.

Power:

Efficient planetary and spur gear transmissions directly transmit the maximum torque to the filling systems.

Efficiency:

Stainless steel screws with various wear coatings ensure a long service life and optimal mass transport. Non-stick linings prevent dry mass from sticking and reduce cleaning effort. Inspection openings on the filling systems make cleaning easy.

Intelligence:

Smart sensor technology monitors the entire extrusion process from vacuum and filling level to mass temperature and pressing pressure.

Intelligent vacuum technology of the latest generation ensures consistent vacuum and prevents boiling in the vacuum chamber.

The illuminated, transparent vacuum chamber is equipped with level measurement and vacuum display.

Various rod and perforated plates are used for optimal perforation and venting of the mass.

Comfort:

The intelligent control system paired with an intuitive operating panel makes handling the extruder easy. The entire extrusion process is continuously monitored and recorded.

Communication with upstream and downstream equipment such as feeders and cutters is standard for our medium-pressure extruders.

Accurate values ensure the quality of the end product.

Contact us.

The latest generation of vacuum extruders from ECT-KEMA is perfectly equipped for the challenging transformation tasks in the energy transition. Especially for the production of high-performance insulators, power, efficiency, intelligence, and of course comfort are required. Our medium-pressure vacuum extruders combine this as a powerful overall package. With screw diameters ranging from 250 to 950 millimeters, they offer the entire range for the production of post insulators, high-voltage supports, and switch chambers.

Power:

Efficient planetary and spur gear transmissions directly transmit the maximum torque to the filling systems.

Efficiency:

Stainless steel screws with various wear coatings ensure a long service life and optimal mass transport. Non-stick linings prevent dry mass from sticking and reduce cleaning effort. Inspection openings on the filling systems make cleaning easy.

Intelligence:

Smart sensor technology monitors the entire extrusion process from vacuum and filling level to mass temperature and pressing pressure.

Intelligent vacuum technology of the latest generation ensures consistent vacuum and prevents boiling in the vacuum chamber.

The illuminated, transparent vacuum chamber is equipped with level measurement and vacuum display.

Various rod and perforated plates are used for optimal perforation and venting of the mass.

Comfort:

The intelligent control system paired with an intuitive operating panel makes handling the extruder easy. The entire extrusion process is continuously monitored and recorded.

Communication with upstream and downstream equipment such as feeders and cutters is standard for our medium-pressure extruders.

Accurate values ensure the quality of the end product.

Contact us.

Vacuum Extruder PVP 250

Application

- Extrusion, kneading and deaeration of plastic and ceramic masses

- Extrusion of solid or hollow bars

- Production of insulators and other technical products from ceramics

Features

ECT-KEMA_PVP250-750_EN

Request

- Diameter: 250 mm

- Max. Pressure: 50 bar / 80 bar

- Throughput rate: 2-4 t/h

- Dimensions: (L/B/H): 3.5 x 1.0 x 1.2 m

ECT-KEMA_PVP250-750_EN

Request

Vacuum Extruder PVP 350

Application

- Extrusion, kneading and deaeration of plastic and ceramic masses

- Extrusion of solid or hollow bars

- Production of insulators and other technical products from ceramics

- with feeding belt and cutting unit

Features

ECT-KEMA_PVP250-750_EN

Request

- Diameter: 350 mm

- Max. Pressure: 50 bar / 80 bar

- Throughput rate: 5-10 t/h

- Dimensions: (L/B/H): 4.3 x 1.3 x 1.8 m

ECT-KEMA_PVP250-750_EN

Request

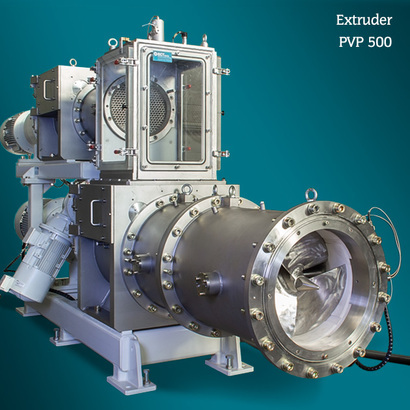

Vacuum Extruder PVP 500

Application

- Extrusion, kneading and deaeration of plastic and ceramic masses

- Extrusion of solid or hollow bars

- Production of insulators and other technical products from ceramics

Features

ECT-KEMA_PVP250-750_EN

Request

- Diameter: 500 mm

- Max. pressure: 40 bar

- Throughput rate: 5-13 t/h

- Dimensions: (L/B/H): 5.0 x 1.5 x 2.3 m

ECT-KEMA_PVP250-750_EN

Request

Vacuum Extruder PVP 750

Application

- Extrusion, kneading and deaeration of plastic and ceramic masses

- Extrusion of solid or hollow bars

- Production of insulators and other technical products from ceramics

Features

ECT-KEMA_PVP250-750_EN

Request

- Diameter: 750 mm

- Max. pressure: 30 bar

- Throughput rate: 8-16 t/h

- Dimensions: (L/B/H): 9.5 x 3.0 x 3.1 m

ECT-KEMA_PVP250-750_EN

Request

Vacuum Extruder PVP 950

Application

- Dosing, cutting, handling of large-format columns

- Horizontal extrusion up to 950 mm auger diameter including modular expansion barrel as well as a transport system with erector for positioning the stacks on the dryer pallet

Features

Request

- Diameter: 950 mm

- Max. pressure: 25 bar

- Throughput rate: 20 t/h

- Dimensions: (L/B/H): 17.3 x 2.5 x 3.5 m

Request